PDF Index

PDF IndexSDT-visc

Contents

Functions

PDF Index

PDF Index |

This section provides tutorial studies based on SDT-visc only.

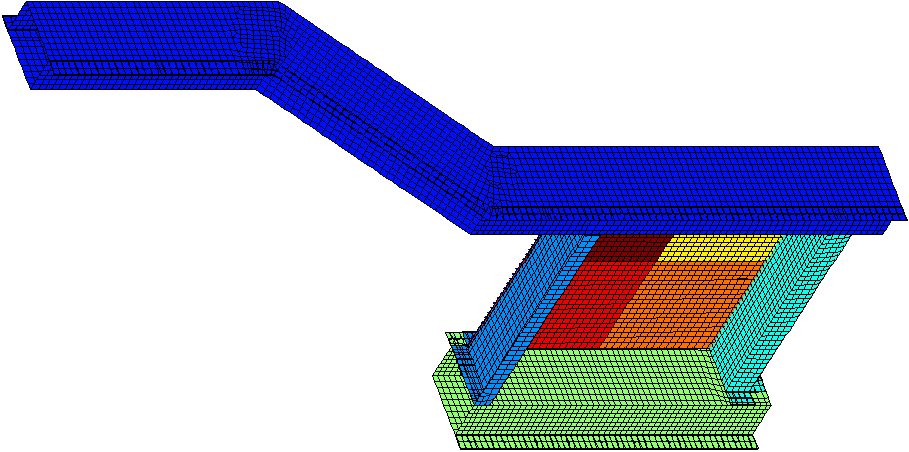

This tutorial uses the cantilever constrained plate shown in the figure below.

d_visco('TutoEhPerf-s1')

meshes a cantilever constrained plate.

d_visco('TutoEhPerf-s1')

meshes a cantilever constrained plate.

step 2 builds a reduced model. One starts by defining a viscoelastic material, and then uses an fe2xf Build call to build the reduced model by learning a soft and a stiff modulus point.

step 2 builds a reduced model. One starts by defining a viscoelastic material, and then uses an fe2xf Build call to build the reduced model by learning a soft and a stiff modulus point.

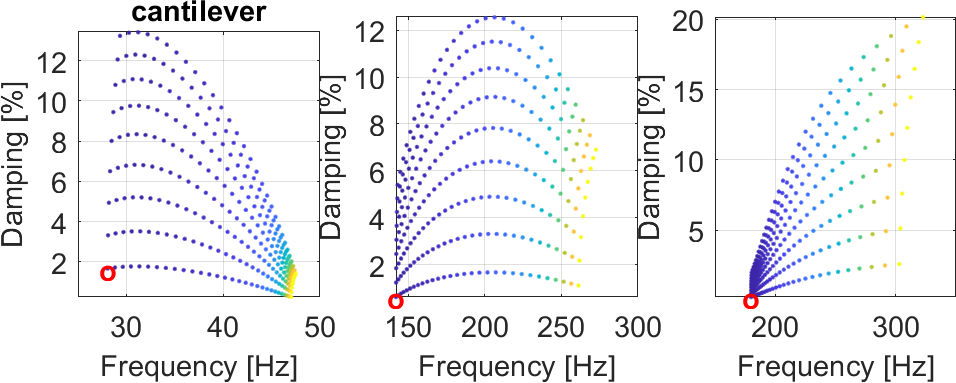

step 3 generates the standard frequency/damping curves for the first 3 modes.

step 3 generates the standard frequency/damping curves for the first 3 modes.

With EhPerf one obtains the damping level as function of modulus and loss factor map. In the present case one sees that the best performance is obtained for a modulus around 2 MPa.

The data used for the E,η performance map is a grid which for each mode can be shown in the frequency damping plane as illustrated below

It may also be interesting to split those maps by mode as shown here.

Older demos are basic_sandwich which generates curves for the validation of shell/volume/shell model used to represent constrained layer treatments as first discussed in section 2.4.

d_visco('TutoPoleRange-s1')

uses a beam with viscoelastic rotational spring example.

d_visco('TutoPoleRange-s1')

uses a beam with viscoelastic rotational spring example.

fevisco handles parametric models with variable stiffness expressed as linear combinations of constant matrices (4.7). The initial step of all parametric studies is to define the parameter sets.

For example, a selection based on ProId.

model=fe_case(model,'par','FrontStruts','-k ProId 168'; 'par','BackStruts' ,'-k ProId 304'};

The PREDIT_mat model XXX

Figure 4.2: The PREDIT_mat model

For example, in the PREDIT_mat model, one can define each of the 4 squares of viscoelastic materials on the pane as a parameter using ProId

cf=feplot(model); MV=cf.mdl; %XXX

One can then visualize each parameter using feplot model properties windows, within the Case tab

Typically, one starts predictions with the a first order approximation to generate a reduced model MVR which is then used to approximate the frequency response functions Rred

Up=d_visco('meshplate upreset'); %Up=fevisco('testplate up'); Up=stack_rm(Up,'mat'); Up = fevisco('addmat 101',Up,'Area1','ISD112 (1993)'); Up = fevisco('addmat 103',Up,'Area2','ISD112 (1993)'); MV=fevisco('makemodel matid 101 103',Up); cf=feplot(MV); cf.Stack{'info','Range'}=[10;30]; cf.Stack{'info','Freq'}=[30:.5:500]'; % Target frequencies Hz cf.Stack{'info','EigOpt'}=[6 40 -(2*pi*30)^2 11]; fe2xf('directfirst zCoef0',cf); ci=iiplot(cf.Stack{'curve','RESP'}); iicom('challDesign point') % This is a call to the new strategy for pole tracking as function of temp RO=struct('IndMode',7:20,'Temp',20:10:100,'Freq',logspace(1,4,20)'); Po=fevisco('poletemp',cf,{'Area1';'Area2'},RO); fe2xf('plotpolesearch',Po)

This is a sample direct computation of the viscoelastic response at 3 frequencies.

d_visco('meshplate matrix');cf=feplot;MV=cf.mdl; cf.Stack{'info','Freq'}=[5:5:40]'; [Rfull,def]=fe2xf('directfull',MV); cf.def=def; % NEED REVISE : iiplot(Rfull);

Given the reduced model MVR you can then track poles through your parametric range using

MVR.Range=[0:10:50]'; Hist=fe2xf('frfpolesearch',MVR); fe2xf('plotpolesearch',Hist) % Generate standard plot of result

The following gives a simple example of a beam separated in two parts. The step12 calls run NASTRAN with the fo_by_set DMAP where an eigenvalue computation is used to generate a modal basis that is then enriched (so called step 1) before generating a parametric reduced model (step 2).

The steps of the procedure are the following

NOTE elements that will be parameterized should have the loss factor of their material set to zero.

These can be easily checked using feplot (open the Edit:Model properties menu and go to the Case tab). cf.sel=selection{1,2} commands. Once the job is written, elements sets will be written in a parameter_sets.bdf file (using nas2up WriteSetC commands).

cf=feplot; % the model should be displayed in feplot cf.mdl=nas2up('JobOpt',cf.mdl); % Init NasJobOpt entry to its default fevisco('writeStep12 -run','RootName',cf) fecom(cf,'Save','FileName'); % save your model for reload

where the write command edits the nominal job files found in sdtdef('FEMLink.DmapDir')).

If you need to edit the bulk file, for job specific aspects of the Case Control Section (definition of MPC and SPC for example), omit the -run, do your manual edits, then run the job (for example nas2up('joball memory=8GB','RootName_step12.dat').

You can also pre-specify a series of EditBulk entries so that your job can run automatically. For example

edits={'insert', 'SOL 103' ,'', 'GEOMCHECK NONE';

'replace', 'SPC = 10','', 'SPC = 1'};

model=stack_set(model,'info','EditBulk',edits);

You are now ready to build the reduced parameterized model using

cf=feplot;fecom(cf,'Load','FileName'); MVR=fevisco('BuildStep12','RootName',model)

If the files are not automatically copied from the NASTRAN server machine, the BuildStep12 -cpfrom makes sure the result file are copied back.

Here is a complete example of this procedure

cd(sdtdef('tempdir')); if ~isunix; return;end % Don't test on windows wd=sdtdef('FEMLink.DmapDir-safe',fullfile(fileparts(which('nasread')),'dmap')); copyfile(fullfile(wd,'fo*.dmp'),'.') copyfile(fullfile(wd,'sdt*.dmp'),'.') !rm ubeam_step12.MASTER ubeam_step12.DBALL ubeam_*.[0-9] model=demosdt('demoubeam');cf=feplot; model=fe_case(model,'dofload','Input', ... struct('DOF',[349.01;360.01;241.01;365.03],'def',[1;-1;1;1],'ID',100)); model=fe_case(model,'par','Top','withnode {z>1}'); model=fe_case(model,'sensdof','Sensors',[360.01]); cf.Stack{'info','EigOpt'}=[5 20 1e3 11]; model=nas2up('JobOpt',model); % Init NasJobOpt entry to its default cf.Stack{'info','Freq'}=[20:2:150]; fevisco('writeStep12 -write -run','ubeam',model); fecom('save','ubeam_param.mat'); % save before MVR is built % you may sometimes need to quit Matlab here if NASTRAN is long cf=feplot('Load','ubeam_param.mat'); % reload if you quit matlab fevisco('BuildStep12','ubeam',cf) fecom('save','ubeam_param.mat'); % save after MVR is built

When dealing with a model that would have been treated through a SOL108 (full order direct frequency response), the parametric model returns a B matrix. This is actually related to the Ke and Kvi matrices by

| (4.9) |

where ηglob is defined in NASTRAN using PARAM,G and the loss factors for the viscoelastic parts using the GE values of the respective components.

For viscoelastic analysis NASTRAN requests a complex curve T(ω) given as two tables. NASTRAN applies the PARAM,G to all elements (the matrix called Kdd1 in NASTRAN lingo is equal to Ke+∑i Kvi) as a result the variable viscoelastic stiffness which are here proportional to G(ω)/Gi,nom = 1+iηglob + T(ω) ηi,nom hence, given the complex modulus, the table is given by

| (4.10) |

Generation of variable coefficients to be used in the toolbox from NASTRAN input is obtained with MVR.zCoefFcn=fevisco('nastranzCoefv1',model).

An alternative to the step12 procedure Viscoelastic computations are performed on an upcom model typically imported from NASTRAN after a SOL103 (real eigenvalue) run with PARAM,POST,-4 to export the element matrices. Thus for a NASTRAN run UpModel.dat which generated UpModel.op2 and where the upcom superelement is saved in UpModel.mat a typical script begins with Up=nasread('UpModel.dat','BuildOrLoad').

In some cases, one may want to use reduced basis vectors that are generated by an external code (typically NASTRAN). The problem is then to generate the reduced model MVR without asking fevisco to generate the appropriate basis. You can simply call the DirectReduced command

Up=d_visco('meshplate upreset'); Up=stack_rm(Up,'mat'); Up = fevisco('addmat 101',Up,'First area','ISD112 (1993)'); Up = fevisco('addmat 103',Up,'Second area','ISD112 (1993)'); def=fe_eig(Up,[6 10 1e3]); MVR = fevisco('makemodel matid 101 103',Up,def); MVR=stack_set(MVR,'info','Freq',[20:.5:90]'); RESP=fe2xf('directreduced',MVR); % Result in XF(1)